NEMA 4X Computer Enclosure Door Benefits

During the manufacturing or assembly process, the food/beverage and pharmaceutical industries must adhere to strict regulations regarding product safety. Contamination must be avoided at all costs. Industrial plants and factories must ensure that all process machinery and equipment, including heavy-duty computer enclosures, are regularly cleaned (usually a sanitizing washdown) and contaminant-free. The decontaminating washdown procedure removes residue and waste materials to preserve the highest pharmaceutical and food/beverage quality.

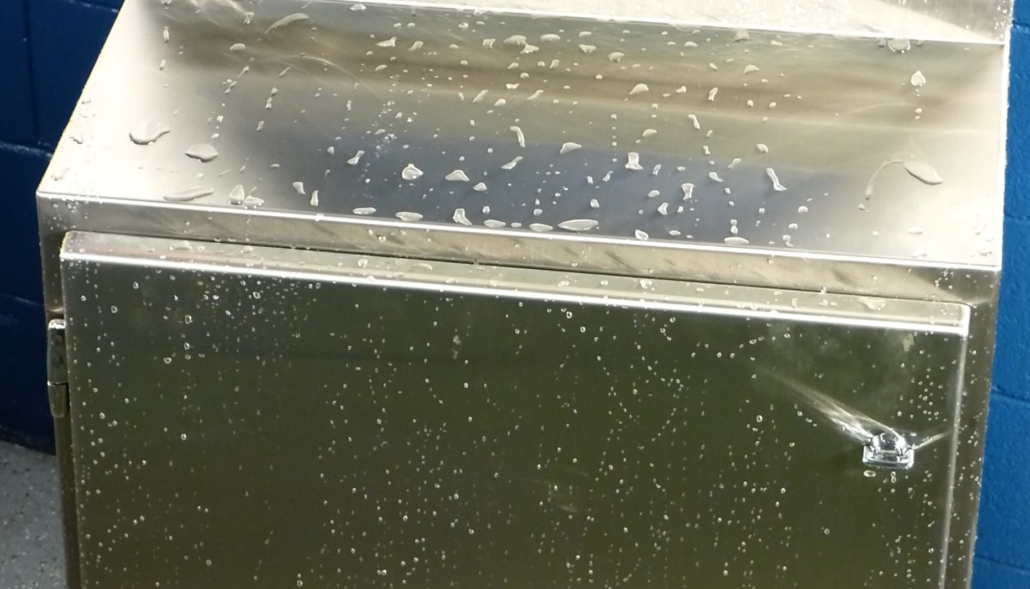

Electronics play a critical role in processing. Due to the harsh environment, a high quality, well-constructed computer enclosure is the key to preventing costly downtime. Type 304 or 316 stainless steel construction (with #3F vertical finish), a sloped design for water run-off, waterproof cable entry, and sanitary legs or pedestal are essential features for a NEMA 4X computer enclosure. However, fine particles and other debris can collect in crevices on the doors.

NEMA 4X computer enclosures should have the following door features to streamline the cleaning process:

Lift Off Hinges — When being deployed in production areas, lift off hinges – with removable pins – are a necessity on a NEMA 4X computer enclosure. These enclosure hinges allow for the door(s) to be easily removed for the detailed cleaning procedure. Specialty hinges will also minimize entrapment of tiny particles. Avoid a NEMA 4X enclosure that utilizes a ‘piano’ style or continuous hinge, because it will be difficult to clean the small crevices during the washdown process.

Latches — Quarter turn or knob style compression latches are ideal for keeping harsh cleaning chemicals far away from internal electronics (computer, printer, monitor), as well as, providing a smooth surface to wash. Traditional lift and turn style latches are undesirable in a washdown application, as these types of latches have too many ‘nooks and crannies,’ making it difficult to clean and keep contaminant free.

Gasket — Dual durometer EPDM gasket (rubber-like and made from ethylene propylene diene monomer), installed around the enclosure doors, offers a strong and durable sealing solution. The gasket’s compression qualities, along with the resistance to liquid/water, will provide high performance protection in any washdown application. Be sure to confirm the enclosure’s gasket and adhesives are compatible with stainless steel and can withstand harsh, high pressure cleaning.

Maintaining sanitary production areas can easily be achieved by selecting computer enclosures that are perfectly designed, well-constructed, and sealed from the outside environment. If you are unsure where to start, consult with a reputable enclosure company that has experience in the food/beverage and/or pharmaceutical industries. When researching the best enclosure solution, always find the product that can withstand the harsh environment in which it will be installed.

HAVE QUESTIONS? LET US KNOW HOW WE CAN BEST ASSIST YOU! CONTACT AN ‘ITSENCLOSURES EXPERT’ AT 1-800-423-9911 -or- SEND US AN EMAIL: INFO@ITSENCLOSURES.CO

Copyright 2023

Copyright 2023  ITSENCLOSURES, 2022

ITSENCLOSURES, 2022