The Best NEMA 4X Computer Enclosure Features

Computer enclosures are often used in the pharmaceutical, food, and beverage industries to protect useful computers, monitors, printers, and keyboards. It is important to specify the correct computer enclosure prior to deploying electronics in a wash down environment. Food, beverage, and pharmaceutical facilities require extreme cleanliness and sanitary conditions. The protective requirement regulations for electronic equipment, deployed in industrial environments, initiated safety classifications to be developed by several manufacturing organizations, notably the National Electrical Manufacturers Association (NEMA).

Industrial enclosure classifications with specific relevance to washdown environments is referred to as NEMA 4X. The operative descriptors for NEMA 4X (indoor or outdoor) enclosures are airtight protection against hose‐directed water and resistance to corrosion and harsh chemicals, which normally dictates stainless steel construction. Proper washdown cleaning can remove the possibility of contamination or costly ‘recalls’ caused by unsanitary conditions.

The following list will help to provide a guideline for features that are critical when researching an enclosure.

4 Features for NEMA 4X Enclosures in Washdown Environments:

- Lift off hinges with removable pins – Lift off hinges create an airtight seal on the door, are quick and easy to clean and can be removed smoothly. Hinges that are continuous (butt, piano, barrel, spring loaded) will not adequately protect the electronics inside of the enclosure and are not designed to counterattack contamination – there are too many crevices for bacterial to form!

Sloped Surface – A sloped work surface or sloped top on a NEMA 4X computer enclosure allows for an acceptable amount of runoff during the cleaning process. The sloping of the enclosure body also ensures that water or liquid will not sit and pool on the top of the computer enclosure. Pooling water can cause damaging germs or bacteria to form. The sloped surface can also significantly reduce a collection of any dust, dirt, grease, or oil.

Sloped Surface – A sloped work surface or sloped top on a NEMA 4X computer enclosure allows for an acceptable amount of runoff during the cleaning process. The sloping of the enclosure body also ensures that water or liquid will not sit and pool on the top of the computer enclosure. Pooling water can cause damaging germs or bacteria to form. The sloped surface can also significantly reduce a collection of any dust, dirt, grease, or oil.

- 304 or 316 Stainless Steel Construction – Stainless steel is a material that is non-porous and therefore impermeable to liquids. In other words, it is waterproof, resists moisture access, and will protect electronics which will be housed in the enclosure. According to AZO Materials, “features of austenitic stainless steel include: excellent corrosion resistance, ductile and readily formable, excellent weldability, hygienic with excellent cleanability, good performance at high temperatures, and excellent performance at low temperatures.”

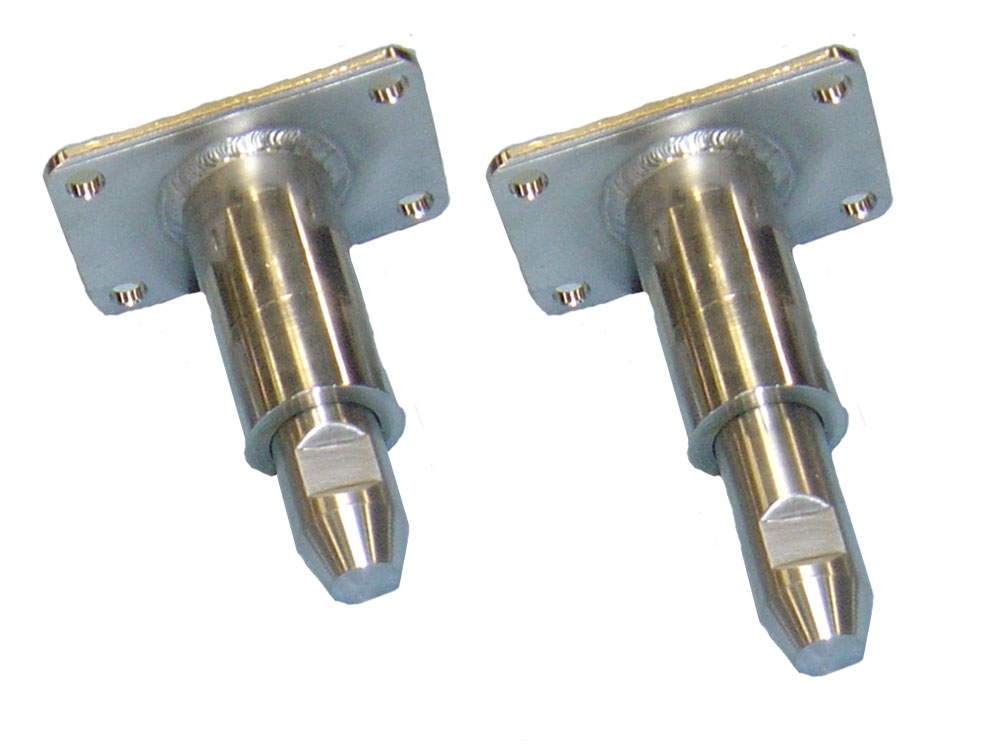

Sanitary Legs – If castors are standard on the NEMA 4X computer enclosure, then consider replacing the castors with stainless steel sanitary legs. Legs will make the enclosure stationary and far more sanitary (castors have nooks and crannies for bacterial). Sanitary legs should be at least 6 inches long, so that the enclosure is not sitting directly on the floor or ground where liquids will pool/puddle. Also, it is smart to always make sure that there is a good amount of space or unobstructed clearance under the enclosure.

Sanitary Legs – If castors are standard on the NEMA 4X computer enclosure, then consider replacing the castors with stainless steel sanitary legs. Legs will make the enclosure stationary and far more sanitary (castors have nooks and crannies for bacterial). Sanitary legs should be at least 6 inches long, so that the enclosure is not sitting directly on the floor or ground where liquids will pool/puddle. Also, it is smart to always make sure that there is a good amount of space or unobstructed clearance under the enclosure.

At various facilities, it is essential to avoid harboring microbial contaminants, which can contaminate food, beverages, or pharmaceuticals. A manufacturing area must always remain sanitary. Unnecessary “product recalls” can cost a company a great deal of money, not to mention bad publicity in the press and on social media. NEMA 4X enclosures ensure that computer equipment is protected and up and running for many years.

Nobody can afford unnecessary downtime. Protecting equipment will also protect the bottom line.

HAVE QUESTIONS? LET US KNOW HOW WE CAN BEST ASSIST YOU! CONTACT AN ‘ITSENCLOSURES EXPERT’ AT 1-800-423-9911 -or- SEND US AN EMAIL: INFO@ITSENCLOSURES.COM

Copyright 2023

Copyright 2023

ITSENCLOSURES, 2022

ITSENCLOSURES, 2022