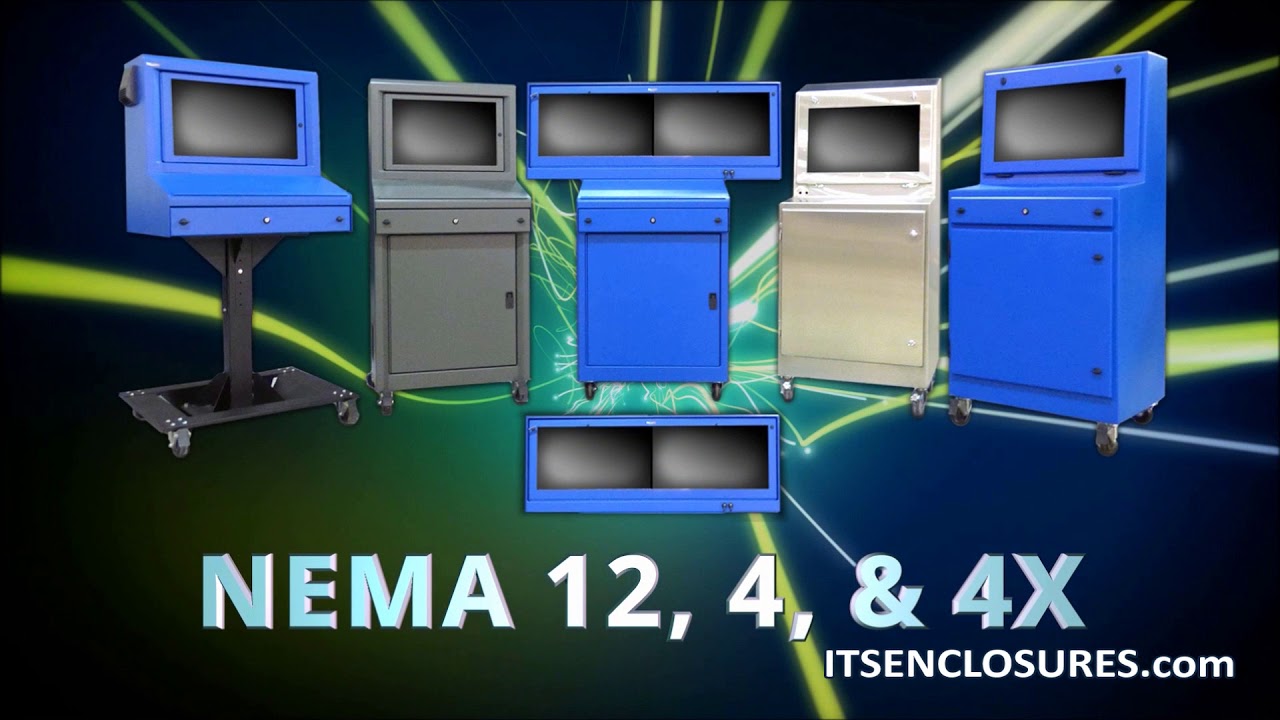

Computer Enclosures & Preventative Maintenance

How can industrial computer enclosures help a manufacturing plant? Like modern medicine, the idea of proactively taking a role in the “health” of electrical equipment will provide great value to a company. If an illness is approaching, the human body has the ability to provide early warning signs. The same can be said about electronics. While the human body has the ability to cure itself of certain illnesses, if a defect appears on the plant floor with machinery, it is just a matter of time before the electronics fail. Unfortunately, electronics do not have the ability to “heal” themselves.

The majority of workers will not exert much concern for maintenance until the process is no longer working as it should. Paying little attention to corrective maintenance, on a regular schedule, will cause electronics housed in industrial computer enclosures to not perform as well as they did upon the original installation. According to the Library at AutomationDirect.com website, “Heat inside an enclosure can decrease the life expectancy of controlling units such as your PLC, HMI, AC drives and other items. Excessive heat can cause nuisance faults from your electrical and electronic components… Heat will also change the expected performance of circuit breakers and fuses, which can cause whole systems to shut down unexpectedly.” Assembling a small team of seasoned electricians and general mechanics is a step in the right direction in realizing the maximum lifetime of critical electronics.

2 Simple Steps to Maximize Lifetime of Electronics

Filter Maintenance

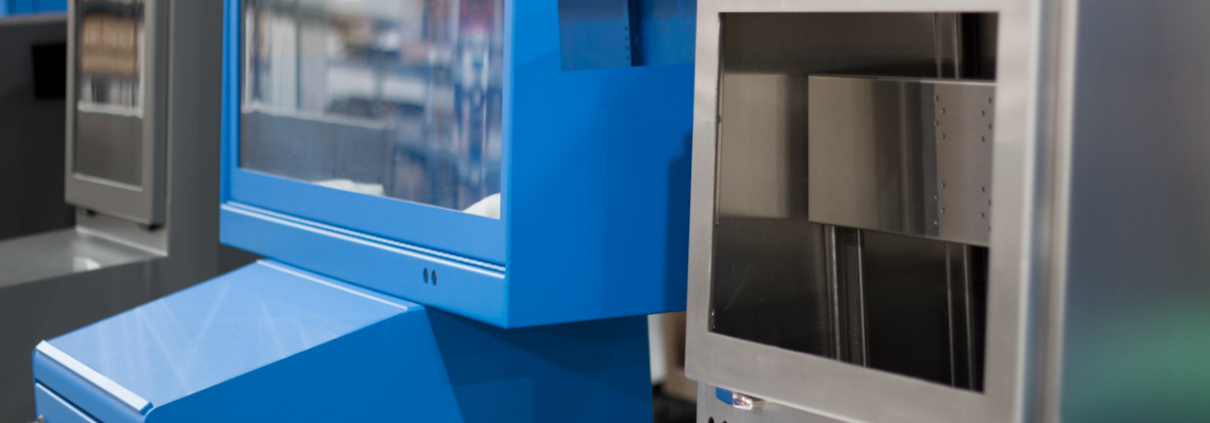

Most industrial computer enclosures utilize at least a fan system or, for warmer environments, an air conditioner. Both cooling systems have a filtering system in place to block particulate matter in the air and prevent dust and dirt from entering the interior of the enclosure. The type of manufacturing environment will dictate how often the filter media needs to be thoroughly cleaned or completely replaced. A filter that has been untouched will eventually impact the functionally of the cooling device, because the system will need to work double (or even triple) as it normally would if clean air were flowing through the schematic. This could lead to the cooling arrangement overcompensating and causing serious failures!

Energy.gov stresses that maintenance is vital, “Neglecting necessary maintenance ensures a steady decline in air conditioning performance while energy use steadily increases… Clogged, dirty filters block normal airflow and reduce a system’s efficiency significantly. With normal airflow obstructed, air that bypasses the filter may carry dirt directly into the evaporator coil and impair the coil’s heat-absorbing capacity. Replacing a dirty, clogged filter with a clean one can lower your air conditioner’s energy consumption by 5% to 15%… Clean or replace your air conditioning system’s filter or filters every month or two during the cooling season. Filters may need more frequent attention if the air conditioner is in constant use, [or] is subjected to dusty conditions.” Property thermal management is beyond crucial to the longevity of electronics within a sealed, industrial computer enclosure.

Keep Industrial Computer Enclosure Doors Closed

As is often the case at many manufacturing plants and factories, people accessing equipment inside of a sealed enclosure tend to get lackadaisical. Carelessness leads to split panels not being properly tightened around important wires and cables entering the industrial computer enclosure or drawers and doors sloppily left open. A lack of willingness to do simple tasks can lead to dust, grease and water finding its way into the enclosure, which is exactly what you want to keep out! One way to prevent these occurrences from happening is to keep the industrial computer enclosures locked at all times. If accessing a printer on a regular basis, check with the enclosure manufacturer about options for a hinged printer door that will minimize the amount of dirt from entering the cabinet.

Keeping a regular maintenance schedule is the best practice for all parties involved in the manufacturing process. It is important to set a schedule and carry through with the plan. Do not let preventative maintenance in your plant become just another “program of the month” that people will forget over time.

Change requires dedication, but will lead to success and a maximum return on the overall industrial computer enclosure investment.

ITSENCLOSURES, 2022

ITSENCLOSURES, 2022  Copyright 2023

Copyright 2023