Cleanliness and NEMA 4X Enclosures

When it comes to maintaining sanitary equipment in the food and beverage industry, operators should be proactive about the overall cleanliness of their facility. In 2011, President Barack Obama signed into law the biggest overhaul of American food safety laws since the 1930s. “The legislation gives the federal Food and Drug Administration the authority to impose new rules to prevent contamination and allows the agency to order, rather than simply suggest, the recall of tainted foods. It also authorizes the creation of a food tracking system to quickly pinpoint the source of outbreaks.”

Food and beverage manufacturing requires very strict cleanliness action plans to prevent catastrophic food problems. Computer systems that operate conveyors and tools/utensils, that are in direct contact with food products, are at high risk for contamination. Food recalls are not a new occurrence, but they can be prevented with well-planned and sanitary practices. Keeping surfaces clean in a plant that produces products for human consumption is extremely imperative.

Being proactive about sanitation can eliminate a potential headache in the future. Building a clean production line starts with sourcing a NEMA 4X computer, printer, electrical, or monitor enclosure that is perfectly designed for wash down applications. Peter Wood, in his article, “Improving Hygiene and Sanitation of Food-Grade Conveyors,“ discussed the importance of NEMA 4X enclosures and equipment, “Food processors require different degrees of sanitation, with meat and dairy processors often relying on the most stringent high pressure wash downs that use caustic cleaning agents that minimize the risk of bacterial growth. To withstand high pressure wash downs, the equipment should feature NEMA 4X- or IP 66-rated electrical enclosures and components while wipe-down sanitation routines demand less water ingress protection.”

What is the most hygienic workstation a manufacturing plant can use?

What is the most hygienic workstation a manufacturing plant can use?

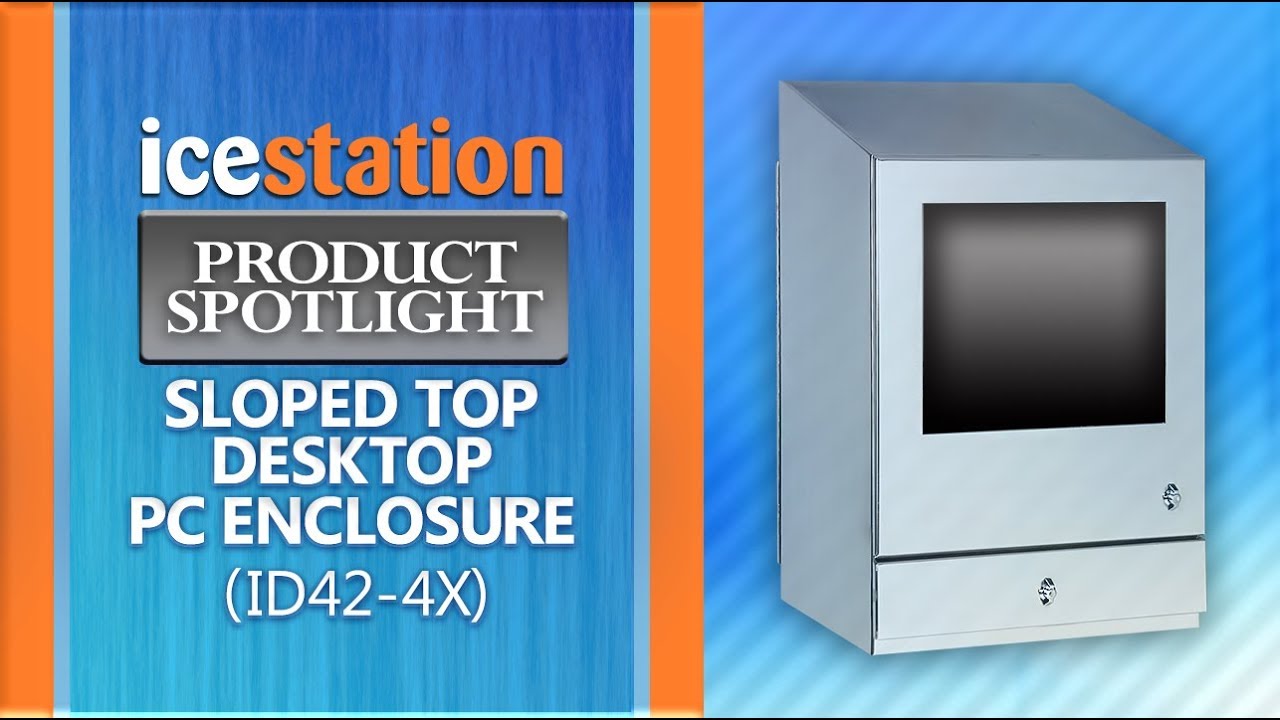

Choose a NEMA 4X enclosure solution that will not harbor microbial contaminants during the sanitation process. The enclosure should feature a sloped top and clean edges to allow for excessive water runoff. Sanitary leg kits are also a popular feature for ensuring that water does not collect under the enclosure, while providing clearance between the NEMA 4X enclosure and the floor. Other popular features include lift off hinges and a minimum of 304 stainless steel construction (316 stainless steel may also be required). Additional considerations include water temperature and chemical mixes and rinses that are used during the wash down process. These items can impact various components that are installed on the computer enclosure, such as gaskets, locks, and window materials.

If feasible, it is recommended that a manufacturing facility make the necessary upgrades to their production line to keep everything sanitary and safe from harm and contamination. It can be detrimental if one area lacks the cleanliness over another. If installing the correct NEMA 4X enclosure, food contamination or a safety recall can be avoided.

Not sure where to start? Speak with an enclosure expert that has experience deploying electronics in a wash down environment.

HAVE QUESTIONS? LET US KNOW HOW WE CAN BEST ASSIST YOU! CONTACT AN ‘ITSENCLOSURES EXPERT’ AT 1-800-423-9911 -or- SEND US AN EMAIL: INFO@ITSENCLOSURES.COM

ITSENCLOSURES, 2022

ITSENCLOSURES, 2022

Copyright 2023

Copyright 2023