Finding the Perfect Label Printer Enclosure

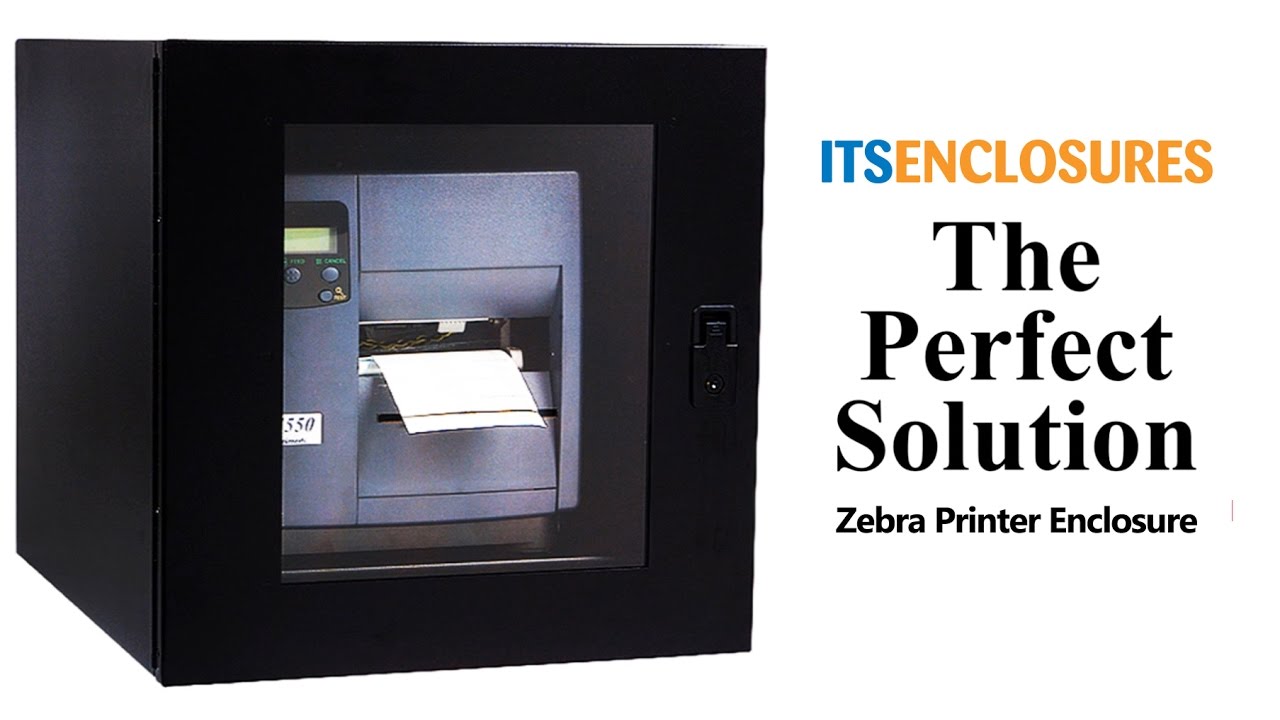

As companies are shipping more items, they need to print more of their own labels for shipments and product tags. In-house thermal label printers are becoming commonplace in manufacturing and industrial fields. Although it is always beneficial to have thermal label printers on the factory floor, these pricey printers cannot be exposed to dust, dirt, grease, or splashing fluids. If overheated or dirty, the printers will be rendered useless. A dust-free, label printer enclosure is the perfect solution for protecting a printer from harsh particles and elements.

When researching a viable, “off the shelf” solution, what should the enclosure include?

4 Valuable Label Printer Enclosure Features:

1. Sliding Shelf

A sliding shelf is ideal for changing the print media and labels, which are normally on the left or right side. Before installation, determine the weight of the printer to make sure the shelf can support the load. To avoid tipping, the enclosure may need to be mounted to a desk or table. Without a sliding shelf, the entire label printer would need to be regularly lifted out of the enclosure to be serviced, which will be difficult on a busy factory floor. The sliding shelf makes the side of the printer easily accessible.

2. Printer Slot

2. Printer Slot

The enclosure’s front door should contain a pre-cut slot for the labels to exit. If not, the door will have to be opened and closed every time labels are printed. Constant opening of the door will negatively affect the enclosure’s seal and could expose the enclosure to environmental threats. There should also be options for the slot location (on the door) at varying locations. Printers are available in many different sizes and the height of the slot is vital for efficiently feeding the labels out of the enclosure.

3. Cable Entry

To maintain a clean and dust-free enclosure, cables, cords, and wires must enter the enclosure through a sealed opening. The label printer enclosure should include some variance of a fastener secured split panel, which will prevent dust or dirt from enclosure entry. A sealed cable entry gland may also be utilized to protect from splashing fluids or liquids. Dust, dirt, and liquids will destroy the printer housed inside of the enclosure, so it is important to keep these contaminants away.

4. Lockable Door with Window

The front door of the label printer enclosure should be lockable with a tightly sealed latch to further protect the printer and eliminate users from changing the printer settings. Simply put, the lock will provide necessary security. A window, on the door, is also helpful, as it will show the printer’s display and offer a way to monitor the labels as they print and feed out of the slot.

As with any enclosure project, be sure to have the exact dimensions of the label printer. Also, make note of the entire wattage of the electronics, in case you will need to add thermal management. Most enclosure companies will supply a thermal management worksheet to determine how much cooling (or heating) may be necessary. Always research before deployment, so that the solution will last forever and a day!

HAVE QUESTIONS? LET US KNOW HOW WE CAN BEST ASSIST YOU! CONTACT AN ‘ITSENCLOSURES EXPERT’ AT 1-800-423-9911 -or- SEND US AN EMAIL: INFO@ITSENCLOSURES.COM

ITSENCLOSURES, 2022

ITSENCLOSURES, 2022  Copyright 2023

Copyright 2023